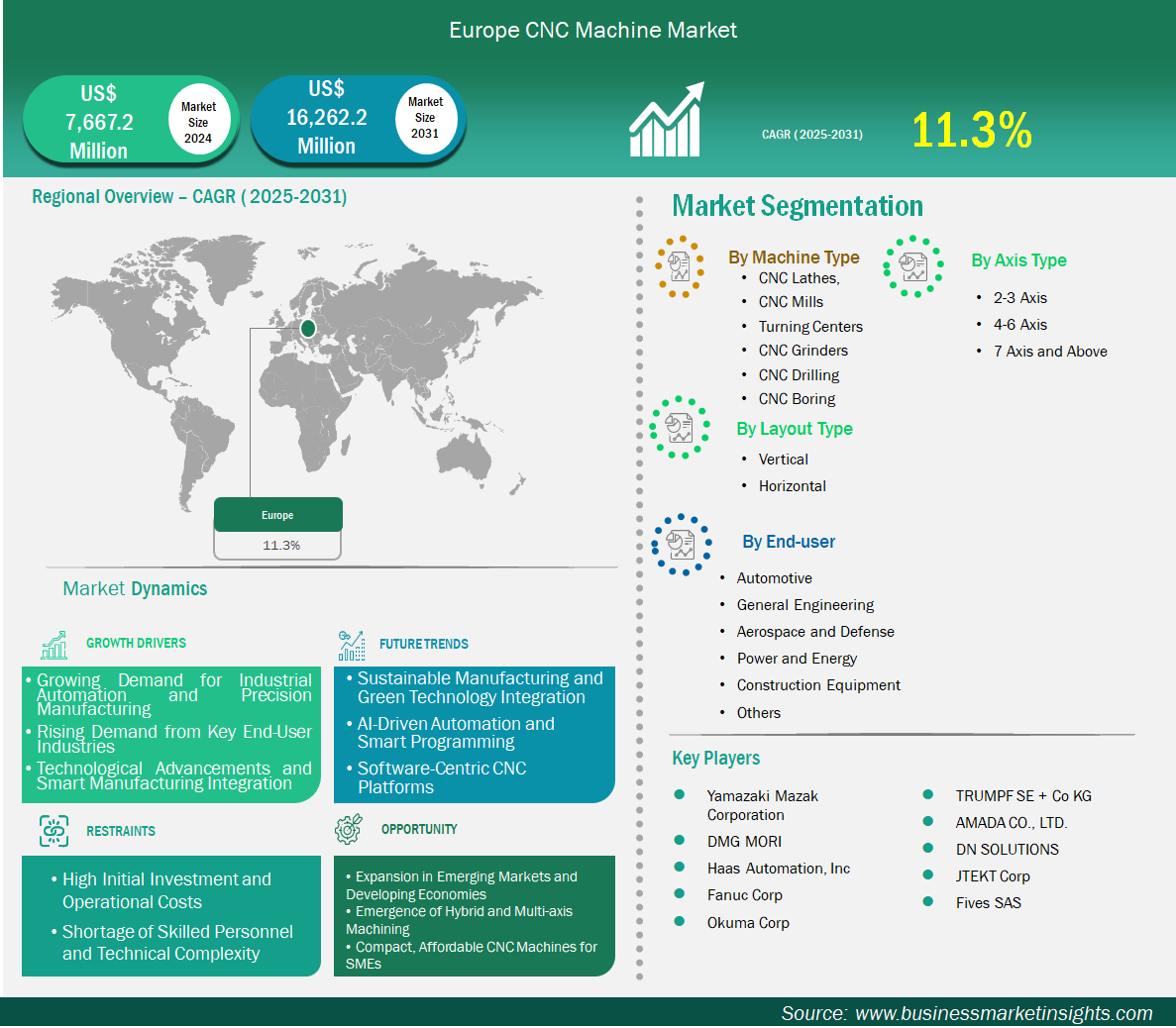

The Europe CNC machine market size is expected to reach US$ 16,262.2 million by 2031 from US$ 7,667.2 million in 2024. The market is estimated to record a CAGR of 11.3% from 2025 to 2031.

Europe holds a significant share of the global CNC machine market. The region's strong industrial heritage, combined with its commitment to innovation and sustainability, creates a sustainable market environment that drives continuous technological advancement and industry transformation.

Germany stands as the undisputed leader in the European CNC machine landscape, leveraging its renowned engineering expertise and robust industrial infrastructure to maintain market dominance. The country's automotive and mechanical engineering sectors serve as primary drivers of CNC machine adoption, with manufacturers increasingly integrating advanced automation technologies to meet stringent quality standards. Italy has established itself as a significant player in the CNC manufacturing sector, with companies like Biesse, SCM Group, and Breton leading innovations in woodworking, metalworking, and stone processing applications. France contributes to the regional market through established manufacturers such as Fives Group, Breton France, and MECANUMERIC, which bring centuries of industrial experience and technological innovation to diverse applications spanning aerospace, automotive, and medical sectors.

The European CNC machine market is experiencing rapid transformation through the widespread adoption of Industry 4.0 technologies, with manufacturers integrating Internet of Things (IoT), artificial intelligence (AI), and data analytics into their operations. This technological evolution enables enhanced automation, predictive maintenance, and real-time monitoring capabilities that significantly improve manufacturing efficiency and product quality. The integration of smart CNC systems supports real-time monitoring and adaptive processing, reflecting the ongoing digital transformation within the continent's manufacturing landscape.

Key segments that contributed to the derivation of the CNC machine market analysis are machine type, layout type, end-user, and axis type.

The European CNC machine market is poised for steady growth, driven by rising automation in manufacturing, demand for precision engineering, and the shift toward Industry 4.0. Key factors include increasing automotive and aerospace production, integration of advanced technologies like AI and IoT, and a growing emphasis on energy efficiency. Additionally, supportive government policies for smart manufacturing and skilled labor availability bolster adoption. Challenges like high initial costs persist, but ongoing digital transformation and innovation in multi-axis machines continue to propel the market forward across diverse industrial sectors.

Growth in the European CNC machine market is further fueled by the resurgence of local manufacturing, customization trends, and the shift toward sustainable production methods. Expanding applications in medical device production and renewable energy sectors are also contributing. Moreover, cross-industry demand for reduced lead times and enhanced design flexibility is encouraging investments in modern, high-performance CNC systems.

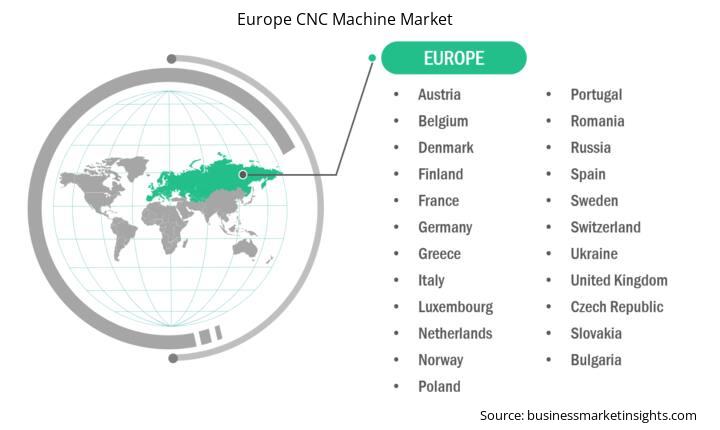

Based on country, the European CNC machine market is further segmented into Germany, Italy, France, the U.K., Spain, Belgium, the Netherlands, Luxembourg, Norway, Finland, Denmark, Sweden, Austria, Switzerland, Russia, Romania, Greece, the Czech Republic, Portugal, Ukraine, Poland, Slovakia and Bulgaria. Germany held the largest share in 2024.

Germany dominates the European market in the CNC machine landscape, owing to its highly advanced manufacturing sector, deep industrial legacy, and continued innovation in mechanical engineering and automation.

The country’s backbone industries—automotive, aerospace, energy, and tooling—have long relied on high-precision CNC systems, and this demand is only intensifying with the shift towards smart factories and Industry 4.0. German companies are at the forefront of integrating IoT, machine learning, and real-time monitoring into CNC platforms, with firms like DMG Mori and Trumpf pioneering hybrid and multi-axis machines that combine milling, turning, and even additive manufacturing in a single unit.

The precision, efficiency, and durability of German-made CNC systems make them highly sought after across global markets. However, despite its technological dominance, Germany faces certain hurdles, such as a maturing workforce, skill shortages among CNC programmers and operators, and the need for SMEs to modernize amid high upfront investment costs. Nevertheless, the government's strong support for digital transformation, coupled with the cultural emphasis on engineering excellence, ensures that Germany’s CNC landscape will remain vibrant and influential.

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 7,667.2 Million |

| Market Size by 2031 | US$ 16,262.2 Million |

| CAGR (2025 - 2031) | 11.3% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Machine Type

|

| Regions and Countries Covered |

Europe

|

| Market leaders and key company profiles |

|

Yamazaki Mazak Corporation, DMG MORI, Haas Automation, Inc , Fanuc Corp, Okuma Corp, TRUMPF SE + Co KG, AMADA CO., LTD., DN SOLUTIONS, JTEKT Corp, and Fives SAS are among the key players operating in the market. These players adopt strategies such as expansion, product innovation, and mergers and acquisitions to stay competitive in the market and offer innovative products to their consumers.

The following methodology has been followed for the collection and analysis of data presented in this report:

The research process begins with comprehensive secondary research, utilizing both internal and external sources to gather qualitative and quantitative data for each market. Commonly referenced secondary research sources include, but are not limited to:

Note: All financial data included in the Company Profiles section has been standardized to US$. For companies reporting in other currencies, figures have been converted to US$ using the relevant exchange rates for the corresponding year.

Business Market Insights conducts a significant number of primary interviews each year with industry stakeholders and experts to validate and analyze the data and gain valuable insights. These research interviews are designed to:

Primary research is conducted via email interactions and telephone interviews with industry experts across various markets, categories, segments, and sub-segments in different regions. Participants typically include:

The Europe CNC Machine Market is valued at US$ 7,667.2 Million in 2024, it is projected to reach US$ 16,262.2 Million by 2031.

As per our report Europe CNC Machine Market, the market size is valued at US$ 7,667.2 Million in 2024, projecting it to reach US$ 16,262.2 Million by 2031. This translates to a CAGR of approximately 11.3% during the forecast period.

The Europe CNC Machine Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the Europe CNC Machine Market report:

The Europe CNC Machine Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The Europe CNC Machine Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the Europe CNC Machine Market value chain can benefit from the information contained in a comprehensive market report.

Please tell us your area of interest

(Market Segments/ Regions and Countries/ Companies)