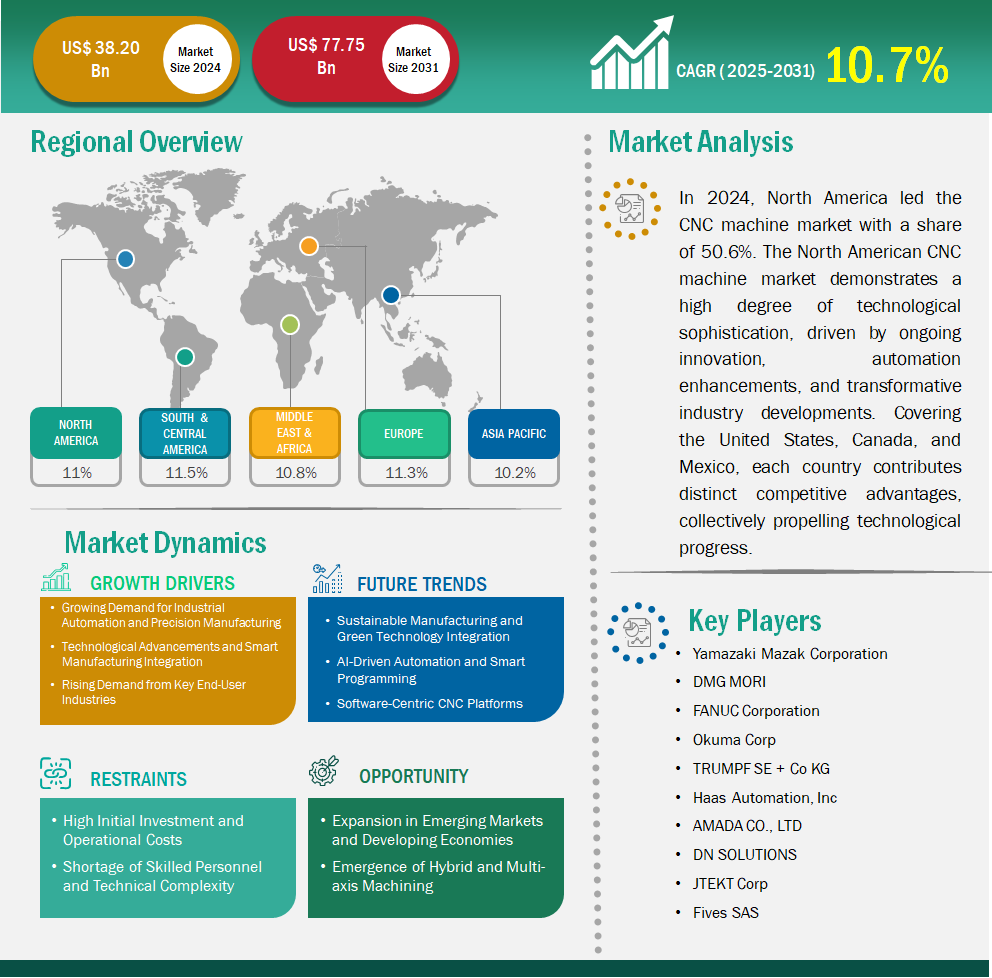

The CNC machine market size is expected to reach US$ 77,754.1 million by 2031 from US$ 38,200.0 million in 2024. The market is estimated to record a CAGR of 10.7% from 2025 to 2031.

Executive Summary and Global Market Analysis:

The CNC machine market represents a critical segment within the global manufacturing landscape, defined by its use of computer-controlled machining tools for tasks such as cutting, milling, drilling, and turning. These machines offer high precision, repeatability, and efficiency, forming the backbone of modern manufacturing processes. As industries demand greater customization, tighter tolerances, and shorter production cycles, CNC machines continue to be a key enabler of industrial advancement across automotive, aerospace, electronics, and heavy machinery sectors. The market’s expansion is supported by continued technological progress in automation, software integration, and tool design, leading to enhanced productivity and reduced human error.

The global CNC machine market demonstrates varied regional dynamics shaped by levels of industrial maturity, economic development, and investment in smart manufacturing. North America leads in both production and consumption, driven by rapid industrial growth, increasing investments in manufacturing automation, and strong demand from sectors such as automotive and electronics. US, Canada, and Mexico serve as major manufacturing hubs, benefiting from supportive government initiatives and cost-effective production capabilities.

Europe holds a competitive position, leveraging its advanced engineering tradition, focusing on Industry 4.0 principles, and emphasis on sustainable and energy-efficient manufacturing. The region's innovation in high-end CNC solutions for aerospace, medical, and automotive sectors continues to stimulate demand. Meanwhile, Asia Pacific exhibits steady growth, bolstered by strong aerospace and defense industries, rising investments in smart factories, and adoption of advanced technologies like AI, IoT, and digital twin systems.

Emerging markets in Latin America, Southeast Asia, and the Middle East & Africa reveal significant potential, although growth may be constrained in the near term by infrastructure gaps and limited technical expertise. However, long-term prospects remain positive due to ongoing industrialization and foreign direct investments. As the global market evolves, trends such as multi-axis machining, hybrid manufacturing, and AI-powered CNC systems are expected to reshape the competitive landscape, offering greater flexibility and scalability across diverse applications.

Key segments that contributed to the derivation of the CNC machine market analysis are machine type, layout type, end-user, and axis type.

CNC Machine Market Drivers and Opportunities:

Growing Demand for Industrial Automation and Precision Manufacturing

As global industries accelerate their transition toward smart manufacturing ecosystems and adopt Industry 4.0 frameworks, CNC (Computer Numerical Control) machines have become fundamental to modern production strategies. Their precision, repeatability, and programmability make them essential for automating workflows and minimizing human error, thereby ensuring consistent product quality and higher operational reliability. These capabilities are particularly valuable in high-stakes industries such as aerospace, automotive, medical devices, and electronics, where dimensional accuracy and compliance with stringent standards are non-negotiable. The ability of CNC machines to operate continuously in 24/7 lights-out environments allows manufacturers to significantly increase throughput and asset utilization without expanding labor or physical infrastructure. This positions CNC systems as a strategic investment for companies focused on scalability, flexibility, and lean production, key pillars in achieving long-term competitiveness in the global marketplace.

Rising Demand from Key End-User Industries

The global CNC machine market is witnessing accelerated growth, driven by widespread adoption across multiple high-growth industries that demand uncompromising levels of precision, repeatability, and efficiency in manufacturing. Among these, the automotive industry remains one of the most significant contributors. As automotive manufacturers push toward electrification, lightweighting, and advanced safety systems, the need for high-precision machining of engine components, transmission systems, brake systems, and structural frames has intensified. CNC machines play a vital role in delivering the accuracy required to produce components with tight tolerances that are critical to both performance and safety. The rise of electric vehicles (EVs) further amplifies demand, as manufacturers need to machine components such as electric drive units, battery housings, and thermal management systems, all of which require high geometric consistency and surface finish capabilities that CNC machines are uniquely equipped to deliver. Furthermore, CNC automation helps meet the automotive sector's stringent production timelines and high-volume output demands, supporting global supply chain continuity.

Emergence of Hybrid and Multi-axis Machining

The convergence of additive and subtractive manufacturing technologies is unlocking transformative capabilities in the CNC machining landscape. Hybrid CNC systems represent a new class of equipment that integrates conventional machining (like milling and turning) with additive manufacturing methods such as Directed Energy Deposition (DED) or laser cladding. This fusion allows for the fabrication of geometrically complex components in a single, seamless workflow—enabling the construction of intricate internal structures like conformal cooling channels, undercuts, and lightweight lattice geometries that would be infeasible using traditional CNC alone. These capabilities are especially vital in high-value industries such as aerospace, defense, and energy, where components must be lightweight yet structurally sound and thermally optimized. For instance, turbine blades and rocket engine parts often require hollow cores or complex surface textures, which hybrid machining can produce with superior control and minimal post-processing.

CNC Machine Market Size and Share Analysis

The global CNC Machine Market, by Machine Type, is segmented into CNC lathes, CNC mills, turning centers, CNC grinders, CNC drilling, and CNC boring. The CNC Drilling segment is expected to witness the highest CAGR in the CNC machine market during the forecast period. CNC lathes represent one of the most fundamental and versatile segments within the computer numerical control machine tools industry. These machines excel in producing cylindrical, conical, and spherical components with exceptional precision and repeatability, making them indispensable across multiple manufacturing sectors. The CNC lathes technology has evolved significantly from traditional manual lathes, incorporating advanced computerized controls that enable automated precision machining with minimal human intervention.

The global CNC Machine Market, by Layout Type, is segmented into vertical and horizontal. The vertical segment held the largest share of the CNC machine market in 2024. Vertical CNC machines, also known as vertical machining centers (VMCs), are characterized by their vertically oriented spindles that move cutting tools perpendicular to the workpiece surface. These machines have established themselves as versatile workhorses in modern manufacturing due to their accessibility, ease of operation, and cost-effectiveness compared to their horizontal counterparts. The vertical configuration provides operators with excellent visibility of the machining process, enabling real-time monitoring and quick adjustments during production runs.

The global CNC Machine Market, by End-user, is segmented into automotive, general engineering, aerospace and defense, power and energy, construction equipment, and others. The Construction Equipment segment is anticipated to witness the highest CAGR in the CNC Machine Market during the forecast period. The automotive industry is a major end user for CNC machines, driven by the ongoing quest for precision, efficiency, and innovation in manufacturing. CNC machining has become essential in automotive production, helping create complex parts that meet strict quality standards while keeping costs down. This technology allows manufacturers to produce key engine parts such as cylinder heads, pistons, camshafts, and engine blocks with high accuracy, ensuring high performance and durability.

The global CNC Machine Market, by Axis Type, is segmented into 2-3 axis, 4-6 axis and 7 axis and above. The 7 Axis and Above segment is anticipated to witness the highest CAGR in the CNC Machine Market during the forecast period. The core segment of the CNC machine market includes 2-axis and 3-axis configurations, serving as the starting point for many manufacturers looking for precision automation solutions. These machines operate along basic linear axes: 2-axis systems usually control X and Y movements, while 3-axis machines add the essential Z-axis for depth control. This segment remains strong owing to its cost-effectiveness and accessibility for small- to medium-sized manufacturing operations.

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 38,200.0 Million |

| Market Size by 2031 | US$ 77,754.1 Million |

| Global CAGR (2025 - 2031) | 10.7% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Machine Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

CNC Machine Market Report Coverage and Deliverables

The "CNC machine market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

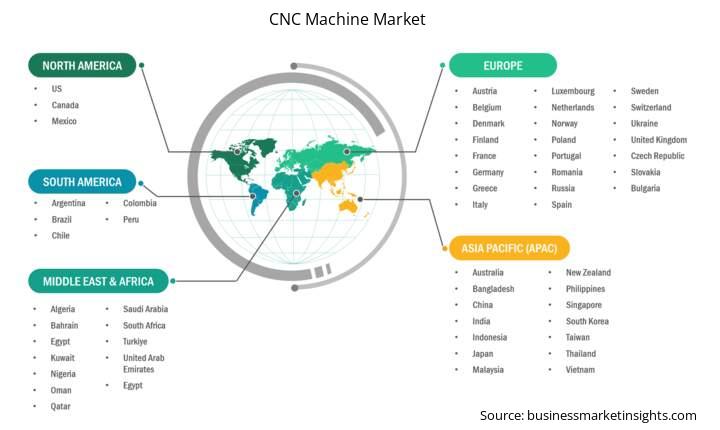

The geographical scope of the CNC machine market report is divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America. The CNC machine market in Asia Pacific is expected to grow significantly during the forecast period.

Asia Pacific has emerged as one of the dominant players in the CNC machine market, establishing itself as both the largest consumer and producer of CNC technology. This expansive market encompasses diverse economies, such as China, Japan, South Korea, India, Australia, and Southeast Asian nations, each contributing unique strengths to the regional manufacturing ecosystem. China stands as the undisputed leader in the Asia Pacific CNC machine landscape. It functions as the world's largest manufacturing hub with extensive networks of CNC machining service providers concentrated in regions like Guangdong, Jiangsu, and Zhejiang. The country produces ~90% of the world's computers, which significantly contributes to the massive use of CNC and advanced manufacturing. Chinese CNC machining services have gained recognition for their cost-effectiveness and high production capacity, making them attractive to global manufacturers seeking efficient solutions.

CNC Machine Market Research Report Guidance

CNC Machine Market News and Key Development:

The CNC machine market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the key developments in the CNC machine market are:

Key Sources Referred:

The CNC Machine Market is valued at US$ 38,200.0 Million in 2024, it is projected to reach US$ 77,754.1 Million by 2031.

As per our report CNC Machine Market, the market size is valued at US$ 38,200.0 Million in 2024, projecting it to reach US$ 77,754.1 Million by 2031. This translates to a CAGR of approximately 10.7% during the forecast period.

The CNC Machine Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the CNC Machine Market report:

The CNC Machine Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The CNC Machine Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the CNC Machine Market value chain can benefit from the information contained in a comprehensive market report.

Please tell us your area of interest

(Market Segments/ Regions and Countries/ Companies)