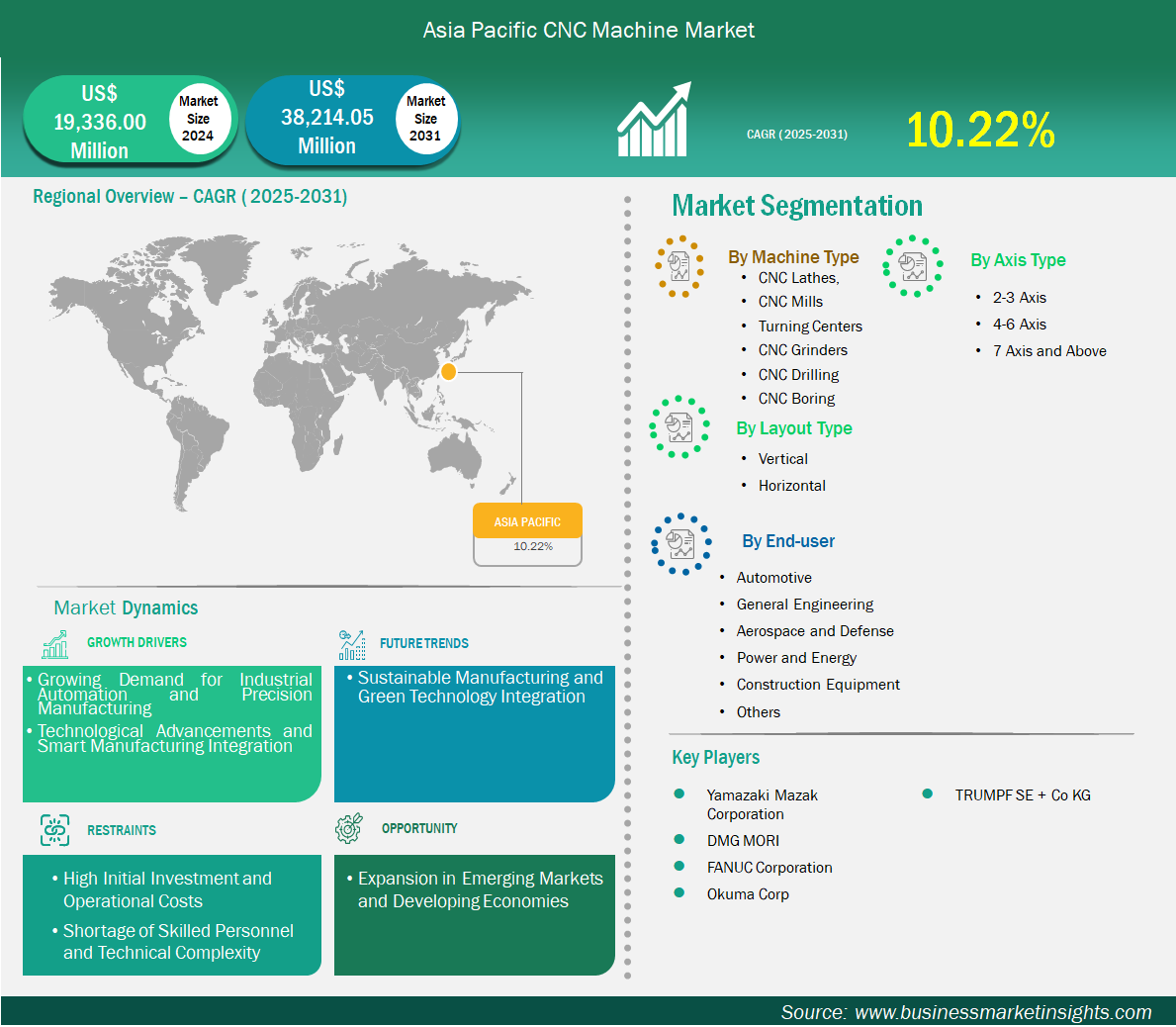

The Asia Pacific CNC machine market size is expected to reach US$ 38,214.1 million by 2031 from US$ 19,336.0 million in 2024. The market is estimated to record a CAGR of 10.2% from 2025 to 2031.

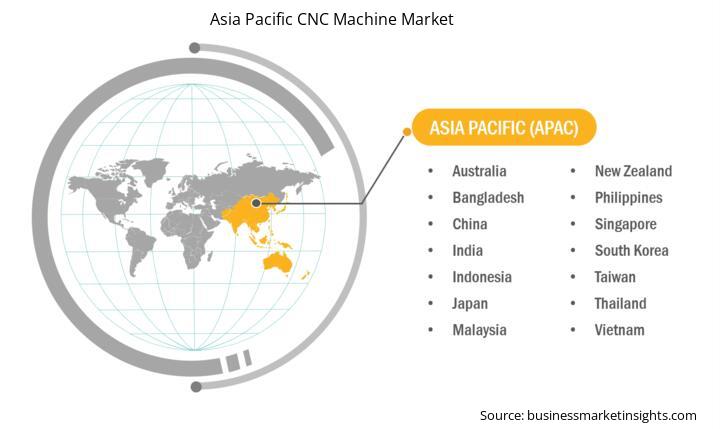

The Asia Pacific CNC machine market represents a dynamic and rapidly evolving landscape characterized by strong industrialization, government-led manufacturing initiatives, and increasing technological adoption. Spanning major economies such as Australia, China, India, Japan, South Korea, Indonesia, Malaysia, the Philippines, Singapore, Thailand, Vietnam, Bangladesh, New Zealand, and Taiwan, plays a pivotal role in global CNC production and consumption. Asia Pacific benefits from a robust manufacturing base, cost-effective labor, and growing demand for precision engineering, making it a global hub for CNC innovation, exports, and industrial automation.

China stands as the dominant force within the Asia Pacific CNC machine market, driven by aggressive industrial modernization, extensive government support through programs like “Made in China 2025,” and its strategic position as the world’s manufacturing powerhouse. The country continues to invest heavily in smart manufacturing technologies, robotics, and high-end CNC systems to transition from low-cost mass production to high-precision and high-value-added manufacturing. China's CNC ecosystem is further strengthened by its vast domestic demand across automotive, electronics, aerospace, and medical device industries. Japan’s CNC machine market is defined by technological excellence, precision engineering, and long-standing expertise in automation. Home to some of the world’s leading CNC manufacturers, Japan maintains a strong focus on ultra-precision machining, high-speed milling, and advanced control systems. The country’s leadership in robotics and mechatronics further reinforces its position in the CNC sector, particularly in applications requiring extreme accuracy, such as medical components, semiconductors, and aerospace parts. India’s CNC machine market is experiencing accelerated growth, fueled by government initiatives like “Make in India,” rising foreign direct investment, and the expansion of key industries such as automotive, defense, and aerospace. Indian manufacturers are increasingly embracing CNC technology to enhance productivity, reduce labor dependency, and meet global quality standards. The growing number of domestic machine tool builders and strategic collaborations with international CNC providers are strengthening India’s position as an emerging CNC manufacturing hub. South Korea and Southeast Asian countries—including Vietnam, Thailand, and Indonesia—are also gaining momentum in the CNC market. South Korea leverages its advanced electronics and automotive industries to drive innovation in CNC applications. At the same time, Southeast Asia benefits from increasing manufacturing offshoring, economic zones, and rising demand for flexible, automated production systems. These nations are becoming attractive alternatives for global manufacturers seeking supply chain diversification beyond China.

The integration of Industry 4.0 technologies is increasingly shaping the Asia Pacific CNC machine landscape. Smart CNC systems equipped with real-time monitoring, IoT sensors, AI-based diagnostics, and cloud-based analytics are being adopted to streamline operations, enhance precision, and enable predictive maintenance. As regional manufacturers strive for greater efficiency, quality, and competitiveness, the convergence of CNC machining with digital technologies is expected to drive the next phase of industrial transformation across the Asia Pacific.

Key segments that contributed to the derivation of the CNC machine market analysis are machine type, layout type, end-user, and axis type.

The Asia Pacific CNC machine market ranks among the most dynamic and rapidly advancing regions globally, characterized by robust manufacturing capabilities, strong government support, and a growing appetite for automation and digitalization. The region’s manufacturing sectors—including automotive, aerospace, defense, electronics, and medical devices—are driving sustained demand for CNC technology due to their increasing focus on precision, productivity, and operational efficiency. Rapid industrialization combined with widespread adoption of Industry 4.0 technologies, such as IoT, AI, and additive manufacturing, is fueling innovation and transforming traditional machining operations across the Asia Pacific.

A key factor propelling growth in this market is the escalating need for high-precision and cost-effective manufacturing solutions that enable companies to reduce cycle times, improve part quality, and increase throughput. Governments in countries like China, India, Japan, and South Korea are actively promoting modernization through initiatives aimed at expanding smart factory infrastructure, supporting domestic CNC manufacturing industries, and encouraging the reshoring of production capabilities. Additionally, rising labor costs and stringent quality standards are prompting manufacturers to invest heavily in advanced CNC machines to maintain global competitiveness.

Based on country, the Asia Pacific CNC machine market is primarily segmented into Australia, China, India, Japan, South Korea, Indonesia, Malaysia, the Philippines, Singapore, Thailand, Vietnam, Bangladesh, New Zealand, Taiwan, and the Rest of Asia Pacific. Among these, China dominates the market due to its advanced industrial infrastructure and strong presence of key CNC machine manufacturers and end-users.

The Asia Pacific CNC machine market is highly heterogeneous, with significant variation in industrial maturity, technology adoption, and market dynamics across key countries:

China is the dominant player in the Asia Pacific CNC space, driven by its vast manufacturing ecosystem and national strategic initiatives such as “Made in China 2025.” The country is rapidly transitioning from low-cost manufacturing to advanced precision machining, leveraging investments in AI-enabled CNC machines, robotics, and automation to support sectors like automotive, aerospace, and electronics. Strong domestic demand, combined with substantial export volumes, underpins China's market leadership.

Japan continues to maintain a leading position in ultra-precision CNC machining technologies. With a strong heritage in robotics and mechatronics, Japan focuses on high-speed milling, multi-axis machining, and the development of highly sophisticated CNC control systems. The country serves high-value sectors such as semiconductor manufacturing, medical devices, and aerospace, emphasizing quality, reliability, and innovation.

India is emerging as a fast-growing market, bolstered by initiatives like “Make in India” that foster manufacturing self-reliance and technological upgrading. Increasing foreign direct investment and partnerships with global CNC technology providers are accelerating adoption, especially in automotive, defense, and aerospace sectors. The market benefits from a growing pool of skilled labor and expanding domestic production capabilities.

South Korea leverages its advanced electronics and automotive industries to drive CNC technology deployment, with a strong emphasis on precision and automation. The country invests heavily in R&D for smart manufacturing and additive hybrid CNC solutions to improve productivity and product quality.

Southeast Asia—including countries such as Vietnam, Thailand, and Indonesia—is experiencing rapid industrial expansion driven by increased foreign investment and manufacturing offshoring. These countries are adopting flexible, scalable CNC technologies to support growing electronics, automotive, and machinery manufacturing hubs.

The Asia Pacific CNC market is highly competitive and innovation-driven, with continuous improvements in software integration, multi-axis machining capabilities, and additive manufacturing hybrid systems. Industry players are focusing on AI-powered CNC machines, IoT-enabled real-time monitoring, and cloud-based analytics to enhance machine uptime, predictive maintenance, and process optimization. The combination of government support, rising industrial automation, and regional supply chain diversification is expected to sustain robust market growth and position the Asia Pacific as a key global hub for advanced CNC machining solutions.

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 19,336.0 Million |

| Market Size by 2031 | US$ 38,214.1 Million |

| CAGR (2025 - 2031) | 10.2% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Machine Type

|

| Regions and Countries Covered |

Asia Pacific

|

| Market leaders and key company profiles |

|

Yamazaki Mazak Corporation, DMG MORI, Haas Automation, Inc , Fanuc Corp, Okuma Corp, TRUMPF SE + Co KG, AMADA CO., LTD., DN SOLUTIONS, JTEKT Corp, Fives SAS are among the key players operating in the market. These players adopt strategies such as expansion, product innovation, and mergers and acquisitions to stay competitive in the market and offer innovative products to their consumers.

The following methodology has been followed for the collection and analysis of data presented in this report:

The research process begins with comprehensive secondary research, utilizing both internal and external sources to gather qualitative and quantitative data for each market. Commonly referenced secondary research sources include, but are not limited to:

Note: All financial data included in the Company Profiles section has been standardized to US$. For companies reporting in other currencies, figures have been converted to US$ using the relevant exchange rates for the corresponding year.

Business Market Insights conducts a significant number of primary interviews each year with industry stakeholders and experts to validate and analyze the data and gain valuable insights. These research interviews are designed to:

Primary research is conducted via email interactions and telephone interviews with industry experts across various markets, categories, segments, and sub-segments in different regions. Participants typically include:

The Asia Pacific CNC Machine Market is valued at US$ 19,336.0 Million in 2024, it is projected to reach US$ 38,214.1 Million by 2031.

As per our report Asia Pacific CNC Machine Market, the market size is valued at US$ 19,336.0 Million in 2024, projecting it to reach US$ 38,214.1 Million by 2031. This translates to a CAGR of approximately 10.2% during the forecast period.

The Asia Pacific CNC Machine Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the Asia Pacific CNC Machine Market report:

The Asia Pacific CNC Machine Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The Asia Pacific CNC Machine Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the Asia Pacific CNC Machine Market value chain can benefit from the information contained in a comprehensive market report.

Please tell us your area of interest

(Market Segments/ Regions and Countries/ Companies)