CNC Turning Centers Market Outlook (2021-2031)

No. of Pages: 450 | Report Code: BMIPUB00032047 | Category: Manufacturing and Construction

No. of Pages: 450 | Report Code: BMIPUB00032047 | Category: Manufacturing and Construction

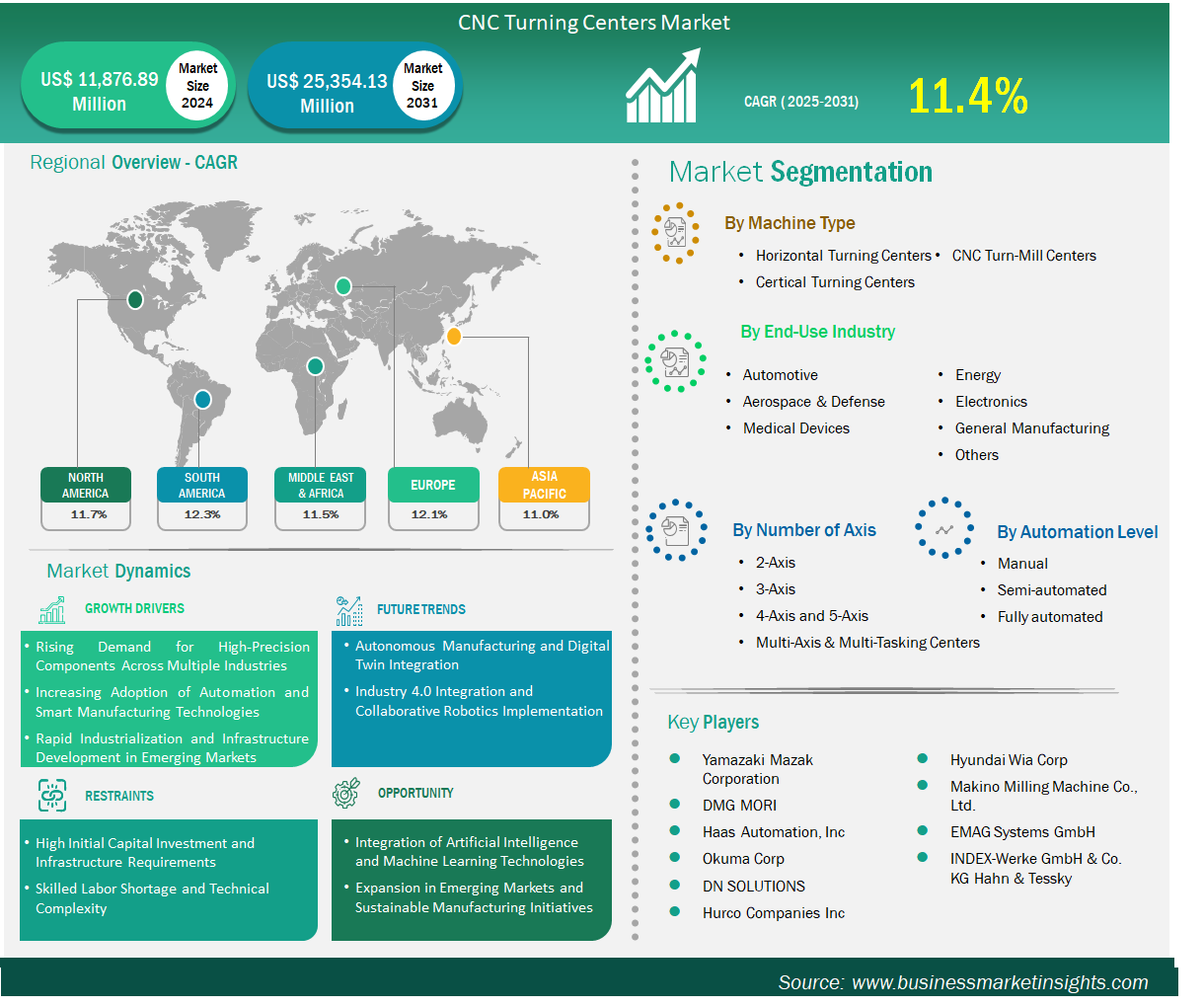

The CNC Turning Centers Market size is expected to reach US$ 25,345.13 million by 2031 from US$ 11,876.89 million in 2024. The market is estimated to record a CAGR of 11.4% from 2025 to 2031.

The global market for CNC turning centers has evolved from a niche segment of traditional lathes to a fundamental component of intelligent manufacturing. Manufacturers now market these machines as adaptable cells capable of autonomous operation, swift changeovers, and combined turning-milling processes, a transformation driven by end-user demands for closer tolerance and reduced lead times. Automotive, aerospace, and medical original equipment manufacturers regard modern turning centers as facilitators of intricate design and supply-chain robustness, leading to the ongoing replacement of outdated equipment with multi-axis, robotic-ready platforms. Ongoing advancements in software, such as tool-path optimization, real-time tool-wear analysis, and integrated digital-twin models, prolong operational lifespan and reduce scrap rates. Sustainability requirements motivate manufacturers to incorporate regenerative drives and coolant-recycling systems, thereby enhancing the value proposition for energy-efficient facilities. Investor interest is reflected in service-oriented pricing strategies and subscription-based software enhancements that lower capital investment barriers for small and medium-sized suppliers.

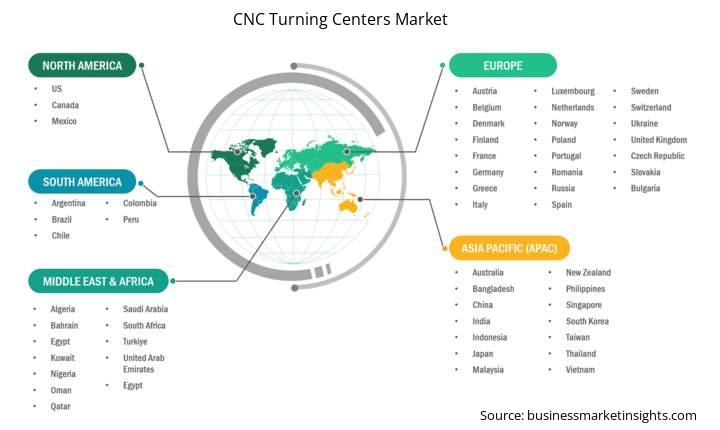

Asia-Pacific possesses the largest installed base of turning centers owing to dense automotive and electronics supply chains, export-oriented policies, and a substantial pool of CNC-skilled labor. China, Japan, and South Korea lead regional demand, while India’s incentive-driven capacity expansions position it as a high-growth contender. European purchasers focus on multi-tasking flexibility and energy efficiency, prompting the adoption of hybrid turn-mill platforms. Meanwhile, North American manufacturing facilities emphasize digitalization and cobot tending to mitigate labor shortages. In the Middle East, expansion within the energy sector is driving orders for large-bore, high-torque lathes. In South America, incremental investments are aligned with cycles in mining and agricultural equipment. The level of competition remains intense: global industry leaders are enhancing adaptive-control software and predictive-maintenance solutions, while regional specialists differentiate themselves through custom tooling and prompt after-sales service. As Industry 4.0 frameworks evolve, a greater integration with MES dashboards, edge analytics, and cloud-based spindle health diagnostics is anticipated to constitute the next phase of competitive advantage.

Key segments that contributed to the derivation of the CNC Turning Centers Market analysis are machine type, number of axes, automation level, and end-user industry.

Rising Demand for High-Precision Components Across Multiple Industries

The CNC Turning Centers Market is experiencing robust growth driven by escalating demand for high-precision components across critical industries including automotive, aerospace, medical devices, and electronics. These sectors require components with exceptional dimensional accuracy and tight tolerances that only advanced CNC turning technology can consistently deliver. The automotive industry, representing a significant portion of market demand, requires precision engine components, transmission systems, and specialized parts that meet stringent quality standards. Similarly, the aerospace and medical device sectors demand complex geometries and mission-critical components where precision and reliability are paramount, making CNC turning centers indispensable for manufacturers seeking to meet these sophisticated requirements.

Integration of Artificial Intelligence and Machine Learning Technologies

The convergence of artificial intelligence and machine learning with CNC turning centers offers transformative opportunities for market expansion and capability enhancement. AI-driven systems facilitate adaptive machining processes that automatically optimize cutting parameters, tool paths, and operational sequences based on real-time sensor data and past performance analyses. Machine learning algorithms support predictive maintenance capabilities that forecast equipment failures, prolong tool life, and schedule maintenance proactively, thereby substantially reducing downtime and operational costs. These intelligent systems learn from production data to consistently improve precision, decrease cycle times, and minimize material waste, providing manufacturers with unprecedented levels of operational efficiency and quality consistency, thereby creating competitive advantages in the realm of precision manufacturing.

The CNC Turning Centers Market is classified by machine type into horizontal, vertical, and CNC turn-mill centers. The horizontal turning centers constitute the predominant segment globally. Horizontal configurations are proficient in processing a diverse range of part geometries, from slender shafts to cylindrical components, establishing them as the preferred option for manufacturers requiring flexibility without sacrificing precision. Their spindle orientation promotes efficient chip evacuation and coolant flow, thereby reducing tool wear and improving surface finishes during prolonged operations.

By automation level, the CNC Turning Centers Market is segmented into manual, semi-automated, and fully automated. The fully automated segment held the largest market share in 2024. Fully automated CNC turning centers are leading the market due to growing demand for high-volume production with minimal labor input. This trend is driven by labor shortages and the need for consistent precision in sectors like automotive and aerospace.

The CNC Turning Centers Market is classified based on the number of axes into 2-axis, 3-axis, 4-axis & 5-axis, as well as multi-axis & multi-tasking centers. 2-axis turning centers retain their dominant position in the market due to their simplicity, versatility, and cost efficiency, rendering them particularly suitable for use within the automotive, aerospace, and electronics sectors. These machines primarily focus on fundamental X and Z movements, making them ideal for the production of cylindrical parts, shafts, and basic contours without incorporating unnecessary complexity. Their straightforward design is well-suited for repetitive tasks in industries such as automotive manufacturing and general fabrication, where priorities include speed and reliability over advanced functionalities.

The CNC Turning Centers Market, categorized according to end-user industry, encompasses the automotive, aerospace and defense, medical devices, electronics, energy, general manufacturing, and other sectors. In 2024, the automotive industry held the predominant share of the market. The automotive sector depends on CNC turning centers for the production of large quantities of symmetrical components such as shafts, pistons, and gears, where consistency and repeatability are of utmost importance. This high-volume focus enables manufacturers to maximize the efficiency of these machines in batch processing, thereby supporting just-in-time inventory strategies and global supply chains.

CNC Turning Centers Market Report Highlights

Report Attribute

Details

Market size in 2024

US$ 11,876.89 Million

Market Size by 2031

US$ 25,345.13 Million

Global CAGR (2025 - 2031) 11.4%

Historical Data

2021-2023

Forecast period

2025-2031

Segments Covered

By Machine Type

By Number of Axes

By Automation Level

By End-Use Industry

Regions and Countries Covered

North America

Europe

Asia-Pacific

South and Central America

Middle East and Africa

Market leaders and key company profiles

The "CNC Turning Centers Market Size and Forecast (2022–2031)" report provides a detailed analysis of the market covering below areas:

The geographical scope of the CNC Turning Centers Market report is divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America. The CNC Turning Centers Market in Asia Pacific is expected to grow significantly during the forecast period.

The Asia Pacific CNC Turning Centers Market is segmented into China, Japan, South Korea, India, Australia, New Zealand, Indonesia, Malaysia, the Philippines, Singapore, Thailand, Vietnam, Taiwan, Bangladesh, and the Rest of Asia. The dominance of the Asia-Pacific region begins with its dense, vertically integrated manufacturing networks. Countries such as China, Japan, South Korea, and India host extensive clusters of component suppliers, contract manufacturers, and OEMs that constitute efficient production ecosystems. CNC turning centers are pivotal to these workflows, facilitating high-precision operations for cylindrical parts across the automotive, electronics, and aerospace sectors. The concentration of such facilities ensures the rapid adoption of machine upgrades, thereby fostering a cycle whereby technological advancements disseminate swiftly among interconnected manufacturing plants.

The CNC Turning Centers Market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the key developments in the CNC Turning Centers Market are:

The CNC Turning Centers Market is valued at US$ 11,876.89 Million in 2024, it is projected to reach US$ 25,345.13 Million by 2031.

As per our report CNC Turning Centers Market, the market size is valued at US$ 11,876.89 Million in 2024, projecting it to reach US$ 25,345.13 Million by 2031. This translates to a CAGR of approximately 11.4% during the forecast period.

The CNC Turning Centers Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the CNC Turning Centers Market report:

The CNC Turning Centers Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The CNC Turning Centers Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the CNC Turning Centers Market value chain can benefit from the information contained in a comprehensive market report.