CNC Mill Market Outlook (2021-2031)

No. of Pages: 450 | Report Code: BMIPUB00032046 | Category: Manufacturing and Construction

No. of Pages: 450 | Report Code: BMIPUB00032046 | Category: Manufacturing and Construction

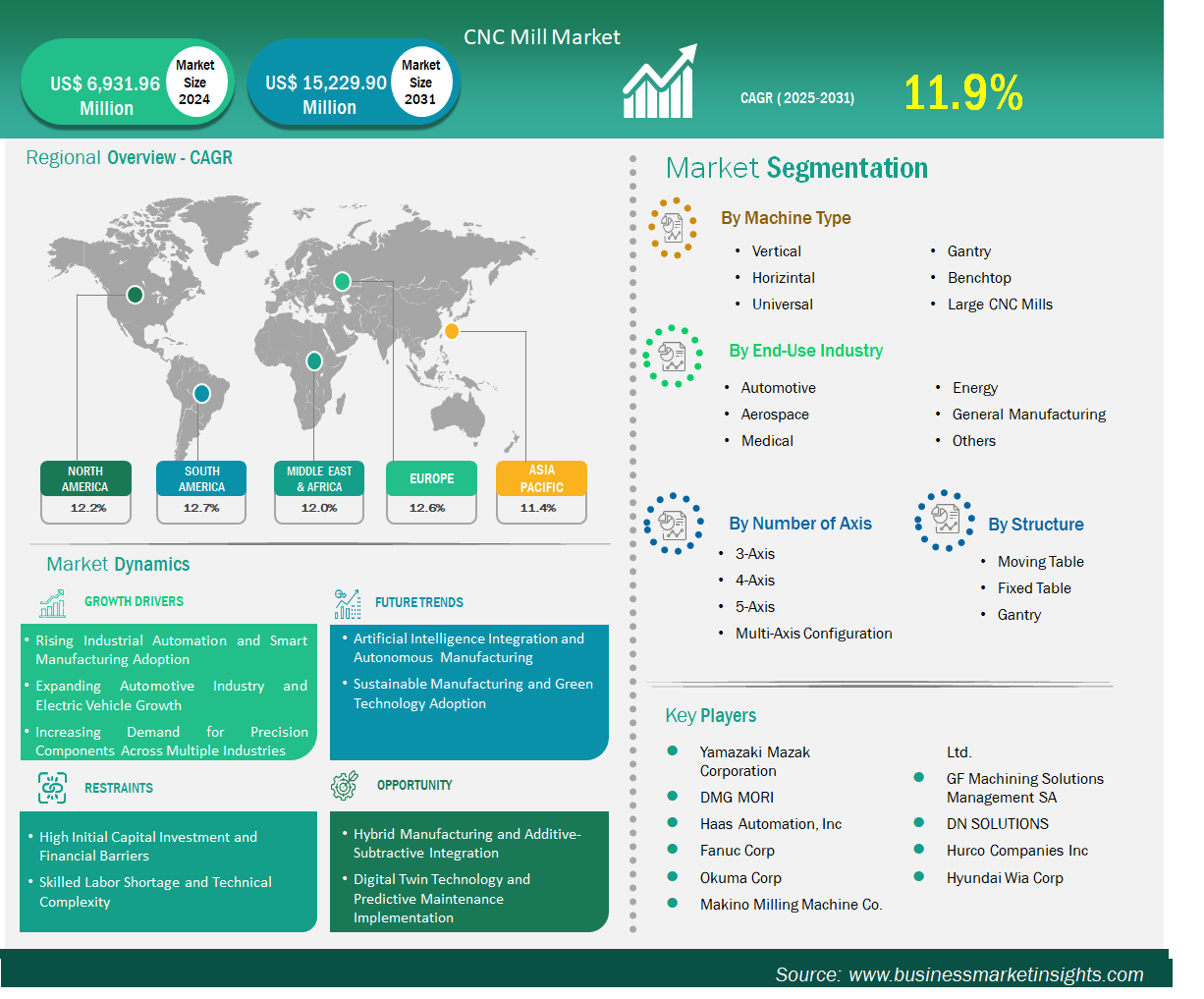

The CNC Mill Market size is expected to reach US$ 15,229.90 million by 2031 from US$ 6,931.96 million in 2024. The market is estimated to record a CAGR of 11.9% from 2025 to 2031.

Executive Summary and Global Market Analysis:

The global CNC mill market serves as a fundamental element of contemporary precision manufacturing, constituting a vital segment within the broader ecosystem of computer numerical control machinery. This advanced market includes automated milling machines that employ computer-controlled systems to execute intricate machining processes with remarkable precision and consistency. The industry has become an essential facilitator of manufacturing excellence across various sectors, establishing itself at the crossroads of traditional machining expertise and innovative digital transformation technologies.

The strategic importance of the market surpasses its immediate operational contributions, functioning as a fundamental catalyst for the deployment of Industry 4.0 across manufacturing sectors. Contemporary CNC milling systems integrate efficiently with Internet of Things (IoT) infrastructure, artificial intelligence algorithms, and predictive maintenance functionalities, thereby transforming conventional manufacturing environments into intelligent, interconnected production ecosystems. This technological advancement has elevated CNC mills from mere manufacturing tools to strategic assets that empower manufacturers to attain unprecedented levels of operational efficiency, consistency in quality, and production adaptability, while also addressing critical issues such as skilled labor shortages and the rising demand for customized manufacturing solutions.

The CNC mill market is undergoing significant transformation propelled by the amalgamation of automation technologies, smart manufacturing principles, and the evolving demands of customers for precision-engineered components. Industry stakeholders observe a fundamental shift from conventional manufacturing paradigms to intelligent, data-driven production systems that enhance resource utilization while ensuring high quality standards. This evolution includes the integration of collaborative robotics, advanced sensor technologies, and machine learning capabilities, which facilitate real-time process optimization and autonomous decision-making within manufacturing operations.

CNC Mill Market Strategic Insights

CNC Mill Market Segmentation Analysis

Key segments that contributed to the derivation of the CNC Mill Market analysis are machine type, number of axes, structure type, and end-user industry.

CNC Mill Market Drivers and Opportunities:

Rising Industrial Automation and Smart Manufacturing Adoption

The global CNC mill market is experiencing robust growth driven by the accelerating adoption of industrial automation and smart manufacturing practices. Manufacturing companies are increasingly integrating CNC technology as part of Industry 4.0 initiatives, leveraging Internet of Things (IoT) sensors, artificial intelligence, and data analytics to optimize production processes. This transformation enables manufacturers to achieve unprecedented levels of operational efficiency, quality consistency, and production flexibility while addressing critical challenges such as skilled labor shortages. The integration of CNC mills with digital technologies creates intelligent, interconnected production ecosystems that support real-time monitoring, predictive maintenance, and autonomous decision-making within manufacturing operations.

Hybrid Manufacturing and Additive-Subtractive Integration

The convergence of additive manufacturing (3D printing) with CNC milling offers significant opportunities for market growth through hybrid manufacturing technologies. This innovative approach merges the fast-prototyping abilities of 3D printing with the high-precision finishing of CNC machining, providing manufacturers with unparalleled design flexibility and production efficiency. Hybrid systems allow the use of metal deposition and material removal tools in the same spindle, enabling complex parts to be built layer by layer through additive processes and then finished with subtractive CNC operations. Companies like Hybrid Manufacturing Technologies have developed retrofit solutions that add additive capabilities to existing CNC machines, drastically reducing costs while broadening operational options. This technology removes the need for multiple machine setups, minimizes material waste, and makes it possible to produce complex geometries that would be hard or impossible to create with either technology alone.

CNC Mill Market Size and Share Analysis

The CNC Mill Market is categorized by machine type into vertical, horizontal, universal, gantry, benchtop, and large CNC mills. The vertical CNC Mills represents the dominant segment worldwide. Vertical mills comfortably transition from roughing to fine finishing, handle a spectrum of materials, and support multi-axis upgrades without fundamental frame changes. Their ability to mill, drill, tap, bore, and even perform light turning in a single setup gives job shops and OEMs a one-machine solution for diverse workpieces.

The CNC Mill Market is categorized by the number of axes into 3-axis, 4-axis, 5-axis, and multi-axis configurations. 3-axis CNC mills maintain market leadership due to their simplicity, versatility, and cost-effectiveness, making them well-suited for the automotive, aerospace, and electronics industries. These machines remain popular because they can handle a wide range of machine operations while maintaining straightforward programming and operation requirements. The 3-axis segment leads the CNC milling tools market due to increasing demand for accurate machining among operators.

The CNC Mill Market is classified by structural category into moving table, fixed table, and gantry models. Our analysis of CNC mills segmented by structure indicates that gantry CNC mills retain the leading position with the largest market share among the categories of moving table, fixed table, gantry, and column configurations. The dominance of gantry CNC mills is attributed to their superior structural rigidity and capability to accommodate large, heavy workpieces. This gantry configuration features a bridge-like framework comprising two vertical columns interconnected by a horizontal beam, thereby ensuring exceptional rigidity and resistance to vibration. Such a durable structure facilitates the mounting of large, heavy workpieces directly on the worktable and supports high-power cutting operations with minimal deflection.

The CNC Mills Market, categorized according to end-user industry, includes automotive, aerospace, medical, energy, general manufacturing, and others. In 2024, the automotive industry held the predominant share of the CNC mill market. The automotive industry sustains its market dominance owing to its extensive scale of production and persistent demand for precision components. The automotive and transportation end-user sector is anticipated to hold the largest portion of the CNC market throughout the forecast period. CNC machinery facilitates increased productivity and cost efficiencies within the automotive sector through automation and streamlined manufacturing processes.

CNC Mill Market Report Highlights

Report Attribute

Details

Market size in 2024

US$ 6,931.96 Million

Market Size by 2031

US$ 15,229.90 Million

Global CAGR (2025 - 2031) 11.9%

Historical Data

2021-2023

Forecast period

2025-2031

Segments Covered

By Machine Type

By Number of Axes

By Structure

By End-Use Industry

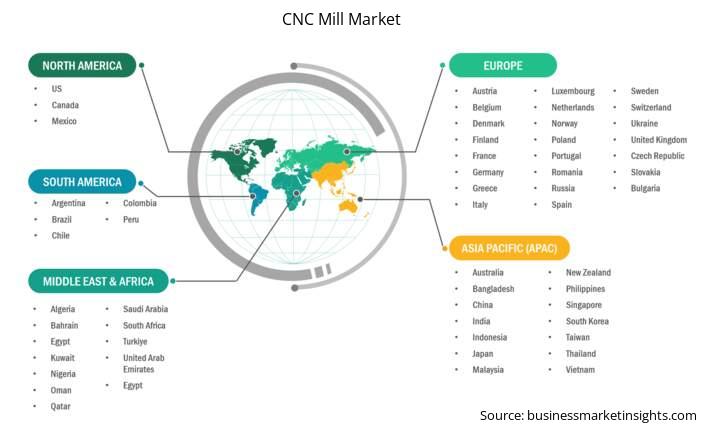

Regions and Countries Covered

North America

Europe

Asia-Pacific

South and Central America

Middle East and Africa

Market leaders and key company profiles

CNC Mill Market Report Coverage and Deliverables

The "CNC Mill Market Size and Forecast (2022–2031)" report provides a detailed analysis of the market covering below areas:

CNC Mill Market Country and Regional Insights

The geographical scope of the CNC Mill Market report is divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America. The CNC Mill Market in Asia Pacific is expected to grow significantly during the forecast period.

The Asia Pacific CNC Mill Market is segmented into China, Japan, South Korea, India, Australia, New Zealand, Indonesia, Malaysia, the Philippines, Singapore, Thailand, Vietnam, Taiwan, Bangladesh, and the Rest of Asia. Asia-Pacific’s dominance begins with its dense, vertically integrated manufacturing corridors. Nations such as China, Japan, South Korea, and India host extensive networks of part suppliers, contract manufacturers, and end-use OEMs that together form highly efficient “one-stop” production pipelines. Because CNC mills sit at the heart of precision machining workflows, regional manufacturers source, install, and upgrade these machines continually to keep the pipeline flowing smoothly. The sheer concentration of facilities ensures that every incremental improvement in spindle speed, tool-changer design, or software capability is quickly diffused across thousands of neighboring plants, reinforcing the platform’s ubiquity.

CNC Mill Market Research Report Guidance

CNC Mill Market News and Key Development:

The CNC Mill Market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the key developments in the CNC Mill Market are:

Key Sources Referred:

The CNC Mill Market is valued at US$ 6,931.96 Million in 2024, it is projected to reach US$ 15,229.90 Million by 2031.

As per our report CNC Mill Market, the market size is valued at US$ 6,931.96 Million in 2024, projecting it to reach US$ 15,229.90 Million by 2031. This translates to a CAGR of approximately 11.9% during the forecast period.

The CNC Mill Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the CNC Mill Market report:

The CNC Mill Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The CNC Mill Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the CNC Mill Market value chain can benefit from the information contained in a comprehensive market report.