CNC Grinder Market Outlook (2021-2031)

No. of Pages: 450 | Report Code: BMIPUB00032045 | Category: Manufacturing and Construction

No. of Pages: 450 | Report Code: BMIPUB00032045 | Category: Manufacturing and Construction

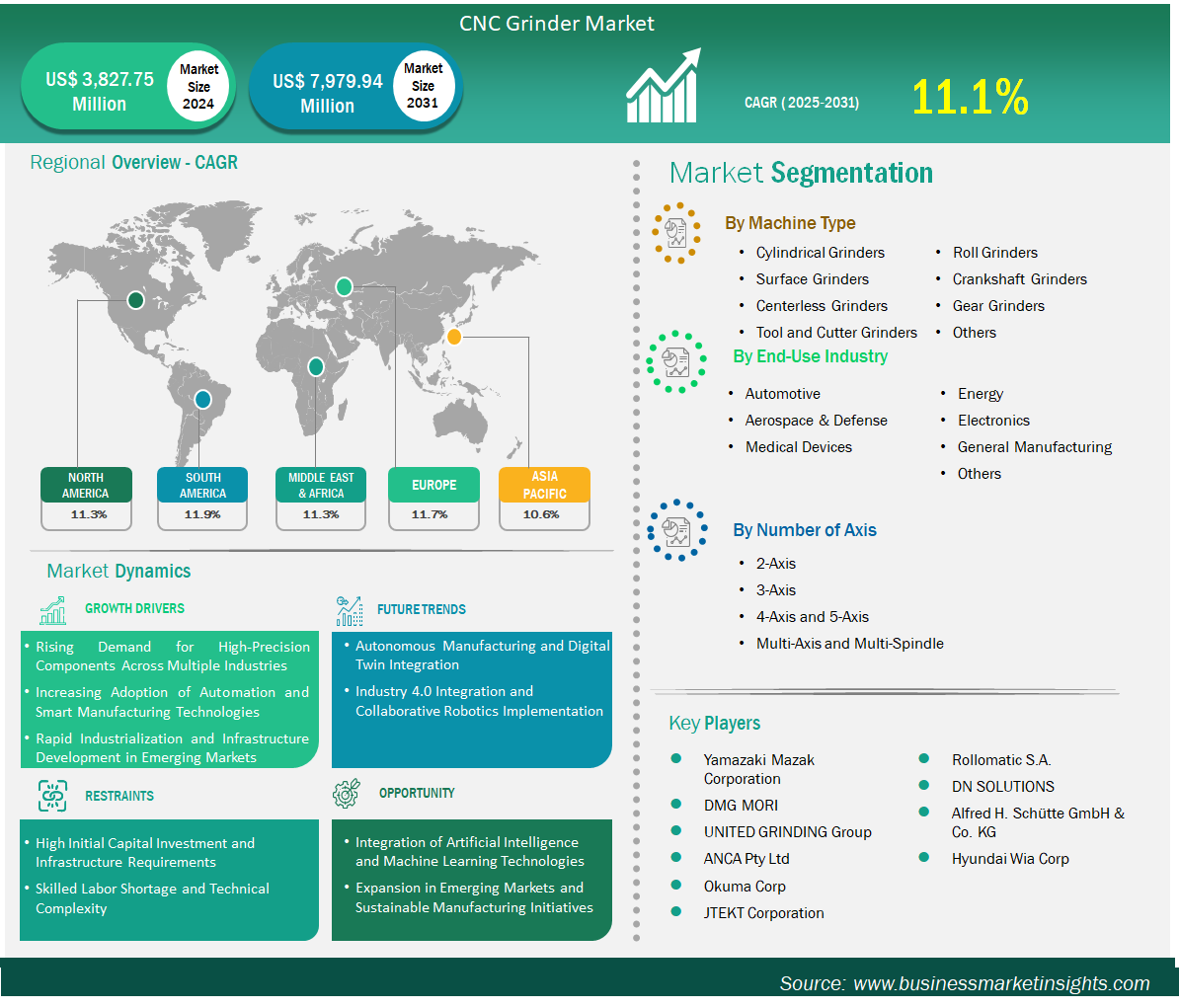

The CNC grinder market size is expected to reach US$ 7,979.94 million by 2031 from US$ 3,827.75 million in 2024. The market is estimated to record a CAGR of 11.1% from 2025 to 2031.

The CNC grinder market represents a vital segment of precision manufacturing, characterized by advanced computer-controlled systems that deliver exceptional accuracy in surface finishing and tool sharpening operations. This market has evolved into a cornerstone of modern industrial processes, supporting diverse applications from component fabrication to custom tooling across multiple sectors. Manufacturers increasingly rely on these machines for their ability to achieve micron-level precision while integrating seamlessly with automation technologies, thereby enhancing productivity and reducing operational inefficiencies. The sector's growth is fueled by ongoing innovations in control systems and abrasive technologies, enabling more efficient material removal and extended machine longevity.

The global CNC grinder market displays distinct regional dynamics influenced by differing levels of industrial progress and technological adoption. Asia-Pacific stands out as a primary growth hub, propelled by swift industrialization and expanding manufacturing capacities within nations possessing robust automotive and electronics industries. The region's focus on cost-efficient production and substantial infrastructure investments encourages the widespread adoption of advanced grinding technologies, further supported by governmental initiatives that promote the integration of smart manufacturing.

In contrast, Europe maintains a strong position through its engineering heritage and focus on precision-intensive industries, where regulatory emphasis on quality and sustainability drives innovation in grinder designs. North America benefits from robust aerospace and medical device manufacturing, with a trend toward automation and digital integration enhancing operational efficiency. Emerging markets in Latin America and the Middle East & Africa demonstrate potential through gradual industrialization, although challenges such as infrastructure limitations may temper short-term expansion. Overall, the market's trajectory indicates a shift toward AI-enhanced systems and collaborative robotics, promising greater versatility across diverse applications.

Key segments that contributed to the derivation of the CNC grinders Market analysis are machine type, number of axes, and end-user industry.

Escalating Demand for High-Precision Manufacturing Components

The CNC grinder market is experiencing robust growth driven by the relentless demand for micron-level precision across critical industries including aerospace, automotive, electronics, and medical devices. Modern manufacturing requires components with increasingly tight tolerances and exceptional surface finishes that only advanced CNC grinding technology can consistently deliver. The aerospace sector requires ultra-precise turbine components, while the automotive industry's shift toward electric vehicles demands precision-engineered powertrain components, battery housings, and lightweight frames. Medical device manufacturing necessitates stringent quality standards for surgical instruments and implants, making CNC grinders indispensable for achieving the required dimensional accuracy and biocompatible surface finishes.

Rapid Expansion in Emerging Markets and Regional Growth

Emerging markets in the Asia-Pacific and Latin America offer significant growth opportunities facilitated by rapid industrialization and increased investments in advanced manufacturing infrastructure. The Asia-Pacific region, in particular, is experiencing notably strong growth, with nations such as China, India, and South Korea making substantial investments in smart manufacturing capabilities and precision grinding technologies. Government initiatives, including India's "Make in India" and "SAMARTH" programs, along with China's manufacturing modernization strategies, establish supportive policy frameworks that expedite the adoption of CNC grinders. The region's expanding automotive industry, burgeoning aerospace sector, and electronics manufacturing industries generate continuous demand for precision grinding solutions.

The CNC grinder market is classified by type into cylindrical grinders, surface grinders, centreless grinders, tool & cutter grinders, roll grinders, crankshaft grinders, gear grinders, and others. The cylindrical CNC grinders constitute the predominant segment globally. Cylindrical grinders are the universal workhorses of precision machining, capable of finishing shafts, pins, bearing races, hydraulic rods, and countless round components. Their ability to handle both external and internal diameters makes them indispensable across automotive, aerospace, energy, and general engineering lines, ensuring the widest installed base among all grinder types.

The CNC grinder market is classified based on the number of axes into 2-axis, 3-axis, 4-axis & 5-axis, as well as multi-axis and multi-spindle grinders. 4-axis & 5-axis machines strike a compelling balance, offering both rotary and linear axes for contouring and helical grinding without venturing into the full complexity and cost of 5-axis systems. This makes them highly attractive for industries requiring both precision and the ability to handle a variety of tool forms—automotive, aerospace, and especially the tooling industry, where tool and cutter grinders are pivotal.

The CNC grinder market, classified by end-user industry, includes the automotive, aerospace and defense, medical devices, electronics, energy, general manufacturing, and other sectors. In 2024, the automotive industry emerged as the largest and most influential end-use segment within the global CNC grinder market. This dominant position underscores the sector’s substantial scale, ongoing innovation, and persistent demand for high-precision components that comply with progressively stringent quality and performance standards. The automotive industry operates at a scale unmatched by other sectors, requiring millions of precision-ground components, such as engine parts, transmission components, bearings, and suspension elements, each year. CNC grinders are essential for achieving the micron-level tolerances and surface finishes demanded by modern automotive engineering.

CNC Grinder Market Report Highlights

Report Attribute

Details

Market size in 2024

US$ 3,827.75 Million

Market Size by 2031

US$ 7,979.94 Million

Global CAGR (2025 - 2031) 11.1%

Historical Data

2021-2023

Forecast period

2025-2031

Segments Covered

By Machine Type

By Number of Axes

By End-Use Industry

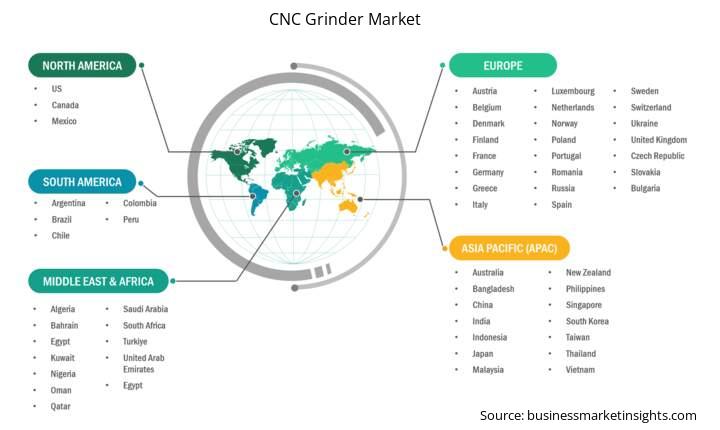

Regions and Countries Covered

North America

Europe

Asia-Pacific

South and Central America

Middle East and Africa

Market leaders and key company profiles

The "CNC grinders Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

The geographical scope of the CNC Grinder Market report is divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America. The CNC grinder market in Asia Pacific is expected to grow significantly during the forecast period.

In 2024, the Asia Pacific region emerges as the predominant leader in the global CNC grinder market by geography. This dominance is quantitatively evidenced within the broader CNC machine tools sector, where Asia-Pacific accounted for more than 50% of the global market share, the largest among all regions—fostered by its expanding manufacturing base, swift industrialization, and vigorous adoption of advanced automation technologies. Although specific market share percentages for CNC grinders, as distinguished from CNC machines overall, are not always explicitly detailed, the qualitative and industrial trends distinctly position Asia-Pacific as the central hub of CNC grinding activity.

The CNC grinders Market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the key developments in the CNC grinders Market are:

The CNC Grinder Market is valued at US$ 3,827.75 Million in 2024, it is projected to reach US$ 7,979.94 Million by 2031.

As per our report CNC Grinder Market, the market size is valued at US$ 3,827.75 Million in 2024, projecting it to reach US$ 7,979.94 Million by 2031. This translates to a CAGR of approximately 11.1% during the forecast period.

The CNC Grinder Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the CNC Grinder Market report:

The CNC Grinder Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The CNC Grinder Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the CNC Grinder Market value chain can benefit from the information contained in a comprehensive market report.