CNC Boring Machine Market Outlook (2022-2031)

No. of Pages: 450 | Report Code: BMIPUB00032044 | Category: Manufacturing and Construction

No. of Pages: 450 | Report Code: BMIPUB00032044 | Category: Manufacturing and Construction

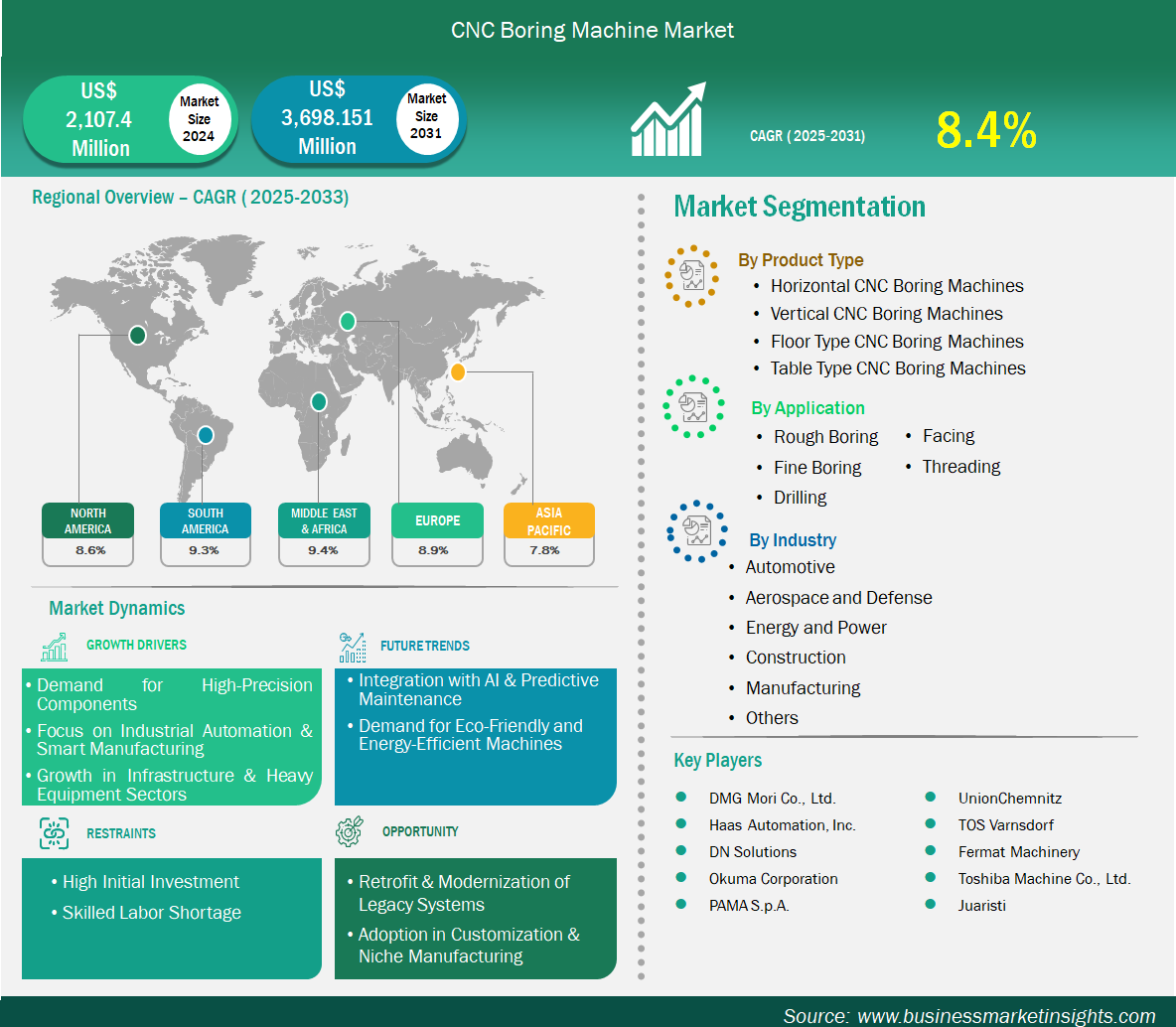

The CNC Boring Machine Market size is expected to reach US$ 3,698.15 million by 2031 from US$ 2,107.40 million in 2024. The market is estimated to record a CAGR of 8.4% from 2025 to 2031.

The CNC Boring Machine Market represents a critical segment of precision machining, enabling high-accuracy hole enlargement and finishing operations within the manufacturing industry. The core meaning of CNC boring lies in its automated, computer-driven process that delivers highly consistent and repeatable internal diameters, especially for complex or deep-hole components. CNC boring machines are widely used in sectors such as automotive, aerospace, heavy machinery, and energy due to their ability to handle tough materials and tight tolerances. The benefits of CNC boring include enhanced production efficiency, minimal human error, increased precision, and the ability to handle custom and high-volume production runs. Additionally, integration with CAD/CAM software allows for faster prototyping and real-time design adjustments, reducing overall lead times.

The usage of CNC boring machines spans multiple industries requiring accurate cylindrical holes, such as engine blocks, hydraulic cylinders, and turbine components. With the rise of Industry 4.0, CNC boring machines are now often equipped with IoT sensors and predictive maintenance capabilities, further improving operational efficiency. Several key factors are driving the growing adoption of CNC boring technology. For instance, the increasing demand for mass customization and high-precision components is pushing manufacturers to turn to CNC automation. At the same time, improvements in tool materials and the development of multi-axis capabilities have made today’s CNC machines more flexible and efficient than ever. Labor shortages, particularly in skilled manual machining, are pushing companies to lean more heavily on automated systems. Beyond that, intense global competition and ongoing pressure to cut operational costs are driving manufacturers to invest in CNC boring technology to keep their edge.

Government incentives for smart manufacturing and increased infrastructure development in emerging economies also contribute to market growth. Further, digital transformation and the trend toward smart factories amplify the demand for CNC boring as part of an integrated, data-driven manufacturing ecosystem. Thus, the CNC boring machine market continues to expand, driven by technological innovation, industrial demand, and the strategic shift toward automation and precision engineering.

Key segments that contributed to the derivation of the CNC Boring Machine Market analysis are product type, application, and industry.

Demand for High-Precision Components

The global demand for high-precision components is a major driver of the CNC boring machine market. Industries such as aerospace, automotive, and defense rely heavily on parts that must meet extremely tight tolerances and maintain consistent quality under demanding conditions. CNC boring machines are engineered to deliver exceptional accuracy and repeatability, making them indispensable in these sectors. As aircraft, defense equipment, and next-generation vehicles incorporate complex designs and lightweight materials, the need for precision machining has intensified. CNC boring machines offer superior dimensional control and automation capabilities, enabling manufacturers to achieve precise fits and finishes while reducing human error and production downtime. Additionally, the rising adoption of Industry 4.0 technologies supports the integration of CNC boring machines into smart manufacturing environments, further enhancing their efficiency and value. As a result, the escalating need for precision across critical industries is expected to significantly boost the global CNC boring machine market in the coming years.

Focus on Industrial Automation & Smart Manufacturing

The global shift towards Industry 4.0 is significantly propelling the growth of the CNC boring machine market, as manufacturers increasingly adopt smart technologies to enhance productivity, efficiency, and flexibility. The integration of Industrial Internet of Things (IIoT), automation, and real-time data analytics enables CNC boring machines to operate with greater precision and adaptability. These machines can now be equipped with sensors and intelligent software that allow for real-time monitoring, predictive maintenance, and adaptive control based on changing production conditions. This level of automation minimizes downtime, reduces waste, and ensures consistent product quality—key factors in competitive manufacturing environments. Additionally, the demand for mass customization and high-mix, low-volume production across industries such as automotive, aerospace, and heavy machinery drives the need for CNC boring machines that can quickly adapt to varying specifications. As a result, smart manufacturing trends are accelerating investments in advanced CNC boring technologies globally, contributing to robust market expansion.

By product type, the CNC boring machine market is segmented into horizontal CNC boring machines, vertical CNC boring machines, floor type CNC boring machines, and table type CNC boring machines. The horizontal CNC boring machines segment dominated the market in 2024. Horizontal CNC boring machines remain prevalent due to due to their capability to handle large workpieces and high-volume production.

By application, the market is segmented into rough boring, fine boring, drilling, facing, and threading. The rough boring segment held the largest share of the market in 2024. The need for improved the precision, repeatability, and efficiency of boring operations. Advanced CNC systems enable manufacturers to achieve tight tolerances and complex geometries, essential for high-quality production in industries such as aerospace, automotive, and energy.

By industry, the market is segmented into automotive, aerospace and defense, energy and power, construction, manufacturing, and others. The automotive segment held the largest share of the market in 2024. The automotive industry increases their need for high-precision production of components like engine blocks and gearboxes.

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 2,107.40 Million |

| Market Size by 2031 | US$ 3,698.15 Million |

| Global CAGR (2025 - 2031) | 8.4% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Product Type

|

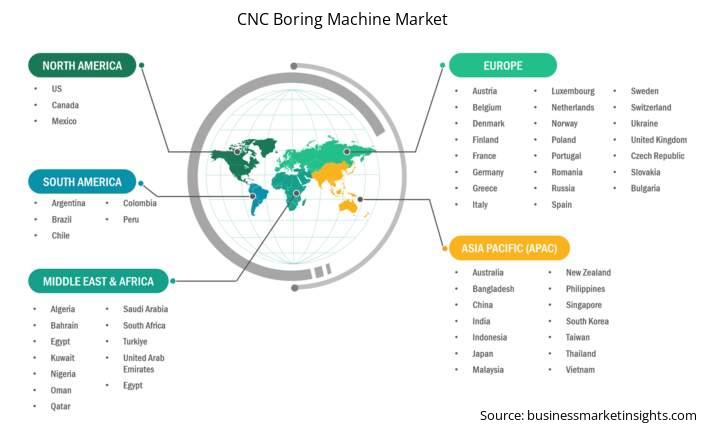

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

|

The "CNC Boring Machine Market Size and Forecast (2022–2031)" report provides a detailed analysis of the market covering below areas:

The geographical scope of the CNC boring machine market report is divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America. The CNC boring machine market in Asia Pacific is expected to grow significantly during the forecast period.

The Asia Pacific CNC boring machine market is segmented into China, Japan, South Korea, India, Australia, New Zealand, Indonesia, Malaysia, the Philippines, Singapore, Thailand, Vietnam, Taiwan, Bangladesh, and the Rest of Asia. Rapid industrialization and economic growth in countries such as China, India, Japan, and South Korea have accelerated demand for precision machining in automotive, aerospace, electronics, and heavy machinery sectors. As manufacturing complexity rises, the need for high-accuracy and efficient machining solutions becomes crucial, positioning CNC boring as an essential technology. Moreover, the rising trend toward customization and small batch production necessitates flexible machining processes, which CNC boring machines facilitate effectively. The competitive pricing of CNC machines due to regional manufacturing and the availability of local after-sales services also lowers barriers to adoption. Collectively, these factors create a conducive environment for increased CNC boring adoption, driving the Asia Pacific region’s manufacturing capabilities to higher levels of sophistication and efficiency.

The CNC boring machine market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the key developments in the CNC boring machine market are:

The CNC Boring Machine Market is valued at US$ 2,107.40 Million in 2024, it is projected to reach US$ 3,698.15 Million by 2031.

As per our report CNC Boring Machine Market, the market size is valued at US$ 2,107.40 Million in 2024, projecting it to reach US$ 3,698.15 Million by 2031. This translates to a CAGR of approximately 8.4% during the forecast period.

The CNC Boring Machine Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the CNC Boring Machine Market report:

The CNC Boring Machine Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The CNC Boring Machine Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the CNC Boring Machine Market value chain can benefit from the information contained in a comprehensive market report.