Published On: Mar 2022

Published On: Mar 2022

The metal segment by material is estimated to lead the market growth during the forecast period.

According to a new market research study of “Asia Pacific Tilt Sensor Market Forecast to 2028 - COVID-19 Impact and Regional Analysis by Material, Technology, Industry and Country.” The Asia Pacific tilt sensor market is expected to reach US$ 155.28 million by 2028 from US$ 96.69 million in 2021. It is estimated to grow at a CAGR of 7.0% from 2021 to 2028. The report highlights trends prevailing in the Asia Pacific tilt sensor market and the factors driving market along with those that act as hindrances.

Industrial robots are used in various industries today, including semiconductors and autos, as well as plastics processing and metal forging. Almost any repetitive task, especially one that is risky or difficult for humans, is ideal for a robot. The use of robots in the manufacturing industry is particularly beneficial. They have traditionally been utilized in high-volume activities, but as technology progresses and the cost of industrial robots decreases, more options and opportunities for medium- and small-scale operations are becoming available.

When combined with other technologies, such as the industrial internet of things (IIoT) or 3D printing robots, industrial robots can deliver improved product quality and more precise and reliable procedures. Other added benefits are reduced cycle durations and real-time monitoring to better preventative maintenance procedures. An industrial robot accelerates the pace of manufacturing operations by running 24 hours a day, seven days a week. Breaks and shift changes are unnecessary for robots.

Robots' speed and dependability help cut cycle time and increase throughput. When robots perform repetitive jobs, workers are less likely to be injured, which is especially important when production occurs in harsh environments. Supervisors can also monitor the procedure from afar, either online or remotely. Having a person oversee many production tasks is frequently more expensive than using a robot. Workers' talents and knowledge can then be applied to other organization segments, such as engineering, programming, and maintenance. A tilt sensor is used to measure tilt angle with a ground plane reference in robotics. Sensors of this type are utilized in industries, service robots, and other domains, such as cellphones, gaming, and planes. Even if a robot moves on its legs or wheels, the inclination must be measured numerous times per second for the robot to retain its position. A tilt sensor measures tendency using one, two, or three axes, and the accuracy varies depending on the sensor. Temperature, gravity, vibration, shock, acceleration/deceleration, and a variety of other noise types all impact accuracy.

The COVID-19 outbreak has resulted in a massive financial loss in APAC. The governments in Asia Pacific countries have taken several crucial steps to contain the spread of the virus by imposing lockdown and physical distancing norms, which has negatively affected the manufacturing sector. China has a significantly large number of electronics and semiconductor manufacturing industries, with numerous manufacturers operating and supporting several industries worldwide.

The Chinese tilt sensor market players have observed a tremendous impact on respective business during Q1 of 2020, which have reflected a stiff decline in revenue generation, which resulted in a loss in China and the APAC tilt sensor market. In addition, China accounts for a significantly higher number of sensor system manufacturers. The lockdown measures and physical distancing norms imposed by the Chinese government during Q1 have reflected a massive fall in the supply of sensor systems, which ultimately resulted in decimated revenue generation in the tilt sensor market.

Construction is more important than ever in this challenging time. The sector has played a crucial role in responding to the crisis and in the recovery, from erecting hospitals in a matter of days to giving lifesaving equipment. The construction industry accounts for 13% of global GDP and increasing labor availability while addressing the most pressing construction-related requirements could assist drive recovery. However, the construction industry has suffered, and numerous countries' construction sites have closed. Most of the open locations have experienced supply chain disruptions and operating constraints. Financial indexes have reflected the disruption: Public engineering, construction, and building materials (ECB) businesses have plummeted much more than the average since 2021. Also, the social distancing norms due to the pandemic have increased the use of robots in various industries, tiling sensors as a significant component. These factors are expected to support the tilt sensors market in APAC.

Based on material, the Asia Pacific tilt sensor market is segmented into metal and non-metal. By technology, the Asia Pacific tilt sensor market is segmented into force balance, MEMS, and fluid-filled. By industry, the Asia Pacific tilt sensor market is segmented into mining & construction, consumer electronics, industrial, automotive, and others. Geographically, the Asia Pacific tilt sensor market is sub-segmented into U.S, Canada and Mexico.

Automation Sensorik Messtechnik GmbH, elobau GmbH & Co. KG, MEMSIC Semiconductor (Tianjin) Co., Ltd., Positek, Welan Technologies Pvt Ltd., Sensata Technologies, Inc., Geosense, Parker Hannifin Corporation, Shanghai Zhichuan Electronic Tech CO., LTD., Ltd and TE Connectivity Corporation are among the leading companies operating in the Asia Pacific tilt sensor market.

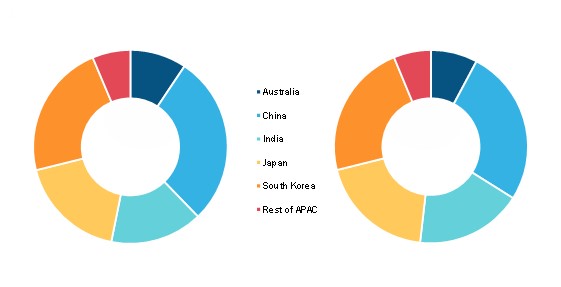

Asia Pacific Tilt Sensor Market, By Country (% Share)

Contact Us

Phone: +16467917070

Email Id: sales@businessmarketinsights.com